Triple Aught Design Fellhoelter Compact Dauntless Review

EDITOR'S NOTE: I am not ashamed to admit it--I am as biased as the next person. I have preferences.

But as a reviewer I want to do what I can to limit their influence on

the score of a product. Most of the time that involves me stating what

they are and noting where opinions may diverge. In some instances, the

biases are so strong I don't feel like I can do a good job reviewing a

product. This was one of those instances. Ben stepped up and filed in

quite nicely. I'd give it the same score, 20 out of 20. I am not sure

if I am willing to give it a perfect score, maybe over time I will.

Despite setting trends that are followed in the production knife world (titanium, framelock, flipper, zzz...), the custom knife scene operates largely on a maker-by-maker, owner-by-owner basis: the purchase and ownership of a custom knife is often about, or at least often becomes about, what rings the buyer’s cherry, and questions of utility and design fall by the wayside in the rarified air of grail knives and acquisition. This is a shame, at least from a gear reviewer’s perspective, because while most customs are doomed to lives as safe queens, and indeed often seemed designed with this end in mind, just as often they are extremely well-designed, and of such a degree of quality that not using them is almost an insult to the knife. I’m happy to say that the Compact Fellhoelter Custom Dauntless (forthwith for brevity’s sake the Compact Dauntless) falls into that second camp. It is beautiful, yes, and certainly collectible, but it is first and foremost a wonderful knife--that is to say a wonderful tool.

Here is the product page on TAD’s website. This knife, which is, of course, not readily available, costs $630. I couldn’t find any written reviews. Here is Tony’s overview, which is the only video commentary I found.

Here is the review sample, Tony’s personal Compact Dauntless:

Twitter Review Summary: Unassailably good design, a wonderful aesthetic, and definite utility make this knife a pleasure to use.

Design: 2

The Compact Dauntless is a product of the Dauntless Project, a sort of design initiative from Triple Aught Design, who led the charge with their own Dauntless knife, and then had custom makers all put their spin on the central concept. This was/is a brilliant idea, and going to TAD’s website and looking at the Dauntless page is, I should warn you, a foray into extremely explicit knife porn (the Jarosz Knives Mod 75, hummuna hummunna).

The conceit for Brian Fellhoelter’s Dauntless is right in the name: it’s compact. Most of the other Dauntless knives, including the flagship production model, are quite large, usually in the neighborhood of 3.5”. Larger knives have their place, and can even be reasonably EDC’d, but to have those Dauntless bones scaled down into something, well, compact and easily pocketable is a wonderful thing. That is the core of the Compact Dauntless’s greatness, but there are many small touches that contribute as well: the way the length of the clip keeps the knife in place in your pocket, the control afforded by the two finger choils, the texturing on the inside of the framelock for disengagement, the raised, jimped area for greater comfort when you’re cutting at an angle...it’s all good. There’s nothing avant-garde about the knife; the Compact Dauntless’s design greatness doesn’t come from wild innovation, but rather from a relentless attention to what works for a knife of its size, and the near-flawless execution thereof.

The blade:handle is .77, nothing inspirational, but this the glory of the Compact Dauntless isn’t in the broad strokes stuff; the details make it great. Also, you’ll notice that the custom TAD hardware looks badass yet still needs just a standard torx driver to disassemble. Hmm, wow, it’s almost like there’s NO REASON to use proprietary screws on a knife, period...

Fit and Finish: 2

No surprises here. We know that production knife companies are capable of absolutely stunning fit and finish, but what I think you get when you step up into a custom is what could almost be called “warmness”: everything that can, and should be smooth, is: all the edges are chamfered, and the seam between the G10 scale and the titanium lockbar side is so tightly done that it passes the fingernail test. I mentioned it above, but there is texturing on the inside of the disengagement area of the lockbar, and it is done so perfectly: it catches your finger without being abrading at all. The fact that the designer’s name and the year of manufacture are machined into the inside of the G10 scale is just too cool. Stunning.

Grip: 2

This knife is a thick little chunk of G10 and titanium, and that, along with the forward choil and smoothed-over overall polish, makes it pretty great in the hand. That being said, there is a small issue with that forward choil: my finger has a tendency to push forward a little bit, right on to the cutting edge, when I’m making a cut of any force. I’m not sure this would be an issue for all users, but if you compare it to the choil on the Strider PT CC, which has a more defined ricasso, or the one on the Caly 3 CF, which is a lot wider and more accommodating, you’ll see that it is lacking.

It may just be the way I hold the knife, and at any rate a modicum of knife sense will alleviate the issue entirely, and so while it’s worth noting, it’s not worth docking this knife a point. And, as also mentioned above, the raised jimping on top not only facilitates traction, but indexes your thumb perfectly for downward cuts.

Carry: 2

This knife is thick, but not obtrusively so, and the long clip keeps it from knocking around at all in your pocket.

It doesn’t disappear, but it doesn’t intrude. Along with my Three Sisters Forge Beast, this knife convinced me of the benefits of a long clip. Very good.

Steel: 2

154CM has always been an underrated steel. In my experience it outperforms VG10 in edge retention (what doesn’t?), sharpens about as easily as AUS-8, and is more durable than S30V. I class it alongside N690, although I’ve never been able to get my 154CM blades as sharp as my N690 ones. This blade uses CPM 154, the powder metallurgy variant of 154CM, which enhances the qualities I like in the standard iteration. I didn’t sharpen this knife, because as this isn’t my blade I didn’t want to wear it down to the point where it would need sharpening, but I do own an Northwoods Knives Indian River Jack and had absolutely no problems getting that thing nice and sharp.

Also I really like the finish on the Compact Dauntless. It looks almost as if it were beadblasted and then stonewashed; whatever was done, the end result is a muted but very attractive finish that I’d imagine, were this knife to be used hard (Tony you should try some batonning!), would wear very well.

Blade Shape: 2

An almost squaloid drop point blade that is proportionally narrower than that of the production Dauntless, with a gracile curve from the main edge up to the point, this blade tells me that Brian Fellhoelter intended for this knife to see actual use: it performs just about any reasonable cutting task with ease. I always find that if I don’t have a lot to say about the shape of the blade, that’s usually because it’s great, and that is certainly the case here.

Grind: 2

The lines of this grind are beautiful. Although I tend to be ambivalent about swedges, the one on the Compact Dauntless is, in keeping with the rest of the knife, perfectly done, and I find that it contributes to the sleek machinist aesthetic of the knife, instead of coming across as “tactical.” The knife is ground from fairly thick stock, and often thicker knives sacrifice too much cutting ability in favor of extra durability. However, the balance is just right here, with the flat grind on the Compact Dauntless, which starts about a third of the way down the blade, steep enough, and the cutting bevel wide and even enough, to ensure good, although not stellar, all-around performance. The beauty of the blade, and the general competence in cutting tasks, as well as the bump in durability over other smallish slicers like the Dragonfly, are enough to warrant two points.

Deployment Method: 2

Tony, in the update to his overview, illustrates the way he found best to open the Compact Dauntless. You may have to think about deploying this knife a little more than you would something with an opening hole, but the tradeoff is a reliable and fast deployment, every single time. That is a point that bears emphasis: the detent is perfectly balanced, and this knife FLIES out of the handle. Even trying, I couldn’t get this knife to open only halfway, or not lock up properly.

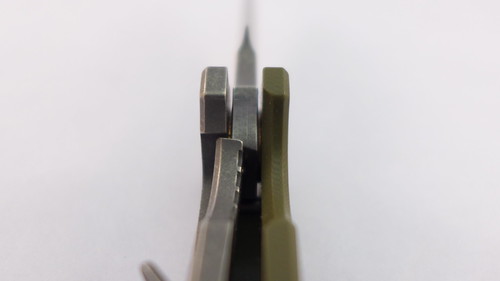

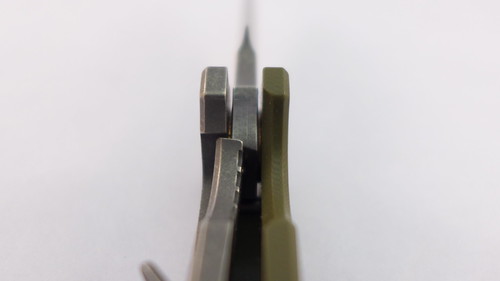

Lock: 2

Framelocks are probably my least favorite knife locks. They have their benefits, I know, but I’ve always found that they are more finicky and require more care than a liner lock or a lockback (which, the longer I use and handle knives, the more I appreciate). Even something more mechanically complex, like an Axis Lock, has been more reliable in my experience. That being said, the Compact Dauntless has the best framelock I’ve ever used. Its lockup is as sure and confident as its deployment.

I can’t tell if the lockface is carbidized or not, and I didn’t get to handle the knife when it was brand new and not broken in, but there is no stickiness at all, and disengagement is effortless, in part due to that great texturing on the lockbar. It’s not going to convince me that framelocks are the way to go, but damn if this isn’t a perfect implementation.

Overall Score: 20 out of 20

When looking at custom knives, there’s this question of whether it’s fair compare them to production knives. This line of thought is to the detriment of the discussion of custom knives: they’re treated as something other than just knives, when in fact, that is often exactly what they are: the ultimate expression of a knife, something in which form and function can meet, unhindered by concerns for budget or manufacturing costs or mass appeal or any of the bullshit that plagues a knife company at the drawing board. Sure, there are display customs, and all custom knives are collectible, but so many makers are out there, putting out knives that are amazing tools in addition to being one of a kind.

The Compact Dauntless is such a knife. I cannot say enough good things about it. The aesthetic is super badass, and the size and fit and finish are unbeatable, but it’s the usefulness that leaves an impression. It’s kind of knife you really appreciate if you’ve already handled and used a bunch of different knives. Almost every detail is thought out and well-realized. This is a knife knut’s knife. The biggest issue here is availability. TAD and Brian, you guys want to get started on a production version?

Despite setting trends that are followed in the production knife world (titanium, framelock, flipper, zzz...), the custom knife scene operates largely on a maker-by-maker, owner-by-owner basis: the purchase and ownership of a custom knife is often about, or at least often becomes about, what rings the buyer’s cherry, and questions of utility and design fall by the wayside in the rarified air of grail knives and acquisition. This is a shame, at least from a gear reviewer’s perspective, because while most customs are doomed to lives as safe queens, and indeed often seemed designed with this end in mind, just as often they are extremely well-designed, and of such a degree of quality that not using them is almost an insult to the knife. I’m happy to say that the Compact Fellhoelter Custom Dauntless (forthwith for brevity’s sake the Compact Dauntless) falls into that second camp. It is beautiful, yes, and certainly collectible, but it is first and foremost a wonderful knife--that is to say a wonderful tool.

Here is the product page on TAD’s website. This knife, which is, of course, not readily available, costs $630. I couldn’t find any written reviews. Here is Tony’s overview, which is the only video commentary I found.

Here is the review sample, Tony’s personal Compact Dauntless:

Twitter Review Summary: Unassailably good design, a wonderful aesthetic, and definite utility make this knife a pleasure to use.

Design: 2

The Compact Dauntless is a product of the Dauntless Project, a sort of design initiative from Triple Aught Design, who led the charge with their own Dauntless knife, and then had custom makers all put their spin on the central concept. This was/is a brilliant idea, and going to TAD’s website and looking at the Dauntless page is, I should warn you, a foray into extremely explicit knife porn (the Jarosz Knives Mod 75, hummuna hummunna).

The conceit for Brian Fellhoelter’s Dauntless is right in the name: it’s compact. Most of the other Dauntless knives, including the flagship production model, are quite large, usually in the neighborhood of 3.5”. Larger knives have their place, and can even be reasonably EDC’d, but to have those Dauntless bones scaled down into something, well, compact and easily pocketable is a wonderful thing. That is the core of the Compact Dauntless’s greatness, but there are many small touches that contribute as well: the way the length of the clip keeps the knife in place in your pocket, the control afforded by the two finger choils, the texturing on the inside of the framelock for disengagement, the raised, jimped area for greater comfort when you’re cutting at an angle...it’s all good. There’s nothing avant-garde about the knife; the Compact Dauntless’s design greatness doesn’t come from wild innovation, but rather from a relentless attention to what works for a knife of its size, and the near-flawless execution thereof.

The blade:handle is .77, nothing inspirational, but this the glory of the Compact Dauntless isn’t in the broad strokes stuff; the details make it great. Also, you’ll notice that the custom TAD hardware looks badass yet still needs just a standard torx driver to disassemble. Hmm, wow, it’s almost like there’s NO REASON to use proprietary screws on a knife, period...

Fit and Finish: 2

No surprises here. We know that production knife companies are capable of absolutely stunning fit and finish, but what I think you get when you step up into a custom is what could almost be called “warmness”: everything that can, and should be smooth, is: all the edges are chamfered, and the seam between the G10 scale and the titanium lockbar side is so tightly done that it passes the fingernail test. I mentioned it above, but there is texturing on the inside of the disengagement area of the lockbar, and it is done so perfectly: it catches your finger without being abrading at all. The fact that the designer’s name and the year of manufacture are machined into the inside of the G10 scale is just too cool. Stunning.

Grip: 2

This knife is a thick little chunk of G10 and titanium, and that, along with the forward choil and smoothed-over overall polish, makes it pretty great in the hand. That being said, there is a small issue with that forward choil: my finger has a tendency to push forward a little bit, right on to the cutting edge, when I’m making a cut of any force. I’m not sure this would be an issue for all users, but if you compare it to the choil on the Strider PT CC, which has a more defined ricasso, or the one on the Caly 3 CF, which is a lot wider and more accommodating, you’ll see that it is lacking.

It may just be the way I hold the knife, and at any rate a modicum of knife sense will alleviate the issue entirely, and so while it’s worth noting, it’s not worth docking this knife a point. And, as also mentioned above, the raised jimping on top not only facilitates traction, but indexes your thumb perfectly for downward cuts.

Carry: 2

This knife is thick, but not obtrusively so, and the long clip keeps it from knocking around at all in your pocket.

It doesn’t disappear, but it doesn’t intrude. Along with my Three Sisters Forge Beast, this knife convinced me of the benefits of a long clip. Very good.

Steel: 2

154CM has always been an underrated steel. In my experience it outperforms VG10 in edge retention (what doesn’t?), sharpens about as easily as AUS-8, and is more durable than S30V. I class it alongside N690, although I’ve never been able to get my 154CM blades as sharp as my N690 ones. This blade uses CPM 154, the powder metallurgy variant of 154CM, which enhances the qualities I like in the standard iteration. I didn’t sharpen this knife, because as this isn’t my blade I didn’t want to wear it down to the point where it would need sharpening, but I do own an Northwoods Knives Indian River Jack and had absolutely no problems getting that thing nice and sharp.

Also I really like the finish on the Compact Dauntless. It looks almost as if it were beadblasted and then stonewashed; whatever was done, the end result is a muted but very attractive finish that I’d imagine, were this knife to be used hard (Tony you should try some batonning!), would wear very well.

Blade Shape: 2

An almost squaloid drop point blade that is proportionally narrower than that of the production Dauntless, with a gracile curve from the main edge up to the point, this blade tells me that Brian Fellhoelter intended for this knife to see actual use: it performs just about any reasonable cutting task with ease. I always find that if I don’t have a lot to say about the shape of the blade, that’s usually because it’s great, and that is certainly the case here.

Grind: 2

The lines of this grind are beautiful. Although I tend to be ambivalent about swedges, the one on the Compact Dauntless is, in keeping with the rest of the knife, perfectly done, and I find that it contributes to the sleek machinist aesthetic of the knife, instead of coming across as “tactical.” The knife is ground from fairly thick stock, and often thicker knives sacrifice too much cutting ability in favor of extra durability. However, the balance is just right here, with the flat grind on the Compact Dauntless, which starts about a third of the way down the blade, steep enough, and the cutting bevel wide and even enough, to ensure good, although not stellar, all-around performance. The beauty of the blade, and the general competence in cutting tasks, as well as the bump in durability over other smallish slicers like the Dragonfly, are enough to warrant two points.

Deployment Method: 2

Tony, in the update to his overview, illustrates the way he found best to open the Compact Dauntless. You may have to think about deploying this knife a little more than you would something with an opening hole, but the tradeoff is a reliable and fast deployment, every single time. That is a point that bears emphasis: the detent is perfectly balanced, and this knife FLIES out of the handle. Even trying, I couldn’t get this knife to open only halfway, or not lock up properly.

Lock: 2

Framelocks are probably my least favorite knife locks. They have their benefits, I know, but I’ve always found that they are more finicky and require more care than a liner lock or a lockback (which, the longer I use and handle knives, the more I appreciate). Even something more mechanically complex, like an Axis Lock, has been more reliable in my experience. That being said, the Compact Dauntless has the best framelock I’ve ever used. Its lockup is as sure and confident as its deployment.

I can’t tell if the lockface is carbidized or not, and I didn’t get to handle the knife when it was brand new and not broken in, but there is no stickiness at all, and disengagement is effortless, in part due to that great texturing on the lockbar. It’s not going to convince me that framelocks are the way to go, but damn if this isn’t a perfect implementation.

Overall Score: 20 out of 20

When looking at custom knives, there’s this question of whether it’s fair compare them to production knives. This line of thought is to the detriment of the discussion of custom knives: they’re treated as something other than just knives, when in fact, that is often exactly what they are: the ultimate expression of a knife, something in which form and function can meet, unhindered by concerns for budget or manufacturing costs or mass appeal or any of the bullshit that plagues a knife company at the drawing board. Sure, there are display customs, and all custom knives are collectible, but so many makers are out there, putting out knives that are amazing tools in addition to being one of a kind.

The Compact Dauntless is such a knife. I cannot say enough good things about it. The aesthetic is super badass, and the size and fit and finish are unbeatable, but it’s the usefulness that leaves an impression. It’s kind of knife you really appreciate if you’ve already handled and used a bunch of different knives. Almost every detail is thought out and well-realized. This is a knife knut’s knife. The biggest issue here is availability. TAD and Brian, you guys want to get started on a production version?